University of Juba, South Sudan 150kW AC Coupled Solar Microgrid Power System

In 2016, South Sudan was in the throes of a civil war. The electrical utility was unreliable, at best, and STEM Synergy had been in the process of initiating a STEM Center (Science, Technology, Engineering, and Mathematics) at the University of Juba for over three years. Given the state of the country, and the utility grid, they came to the conclusion that a Solar Microgrid would be the best option to provide power to the STEM Center. Due to the size of the system required for the center, and the fact that the majority of their energy would be used during the day, the best type of system for their purposes is an AC Coupled System.

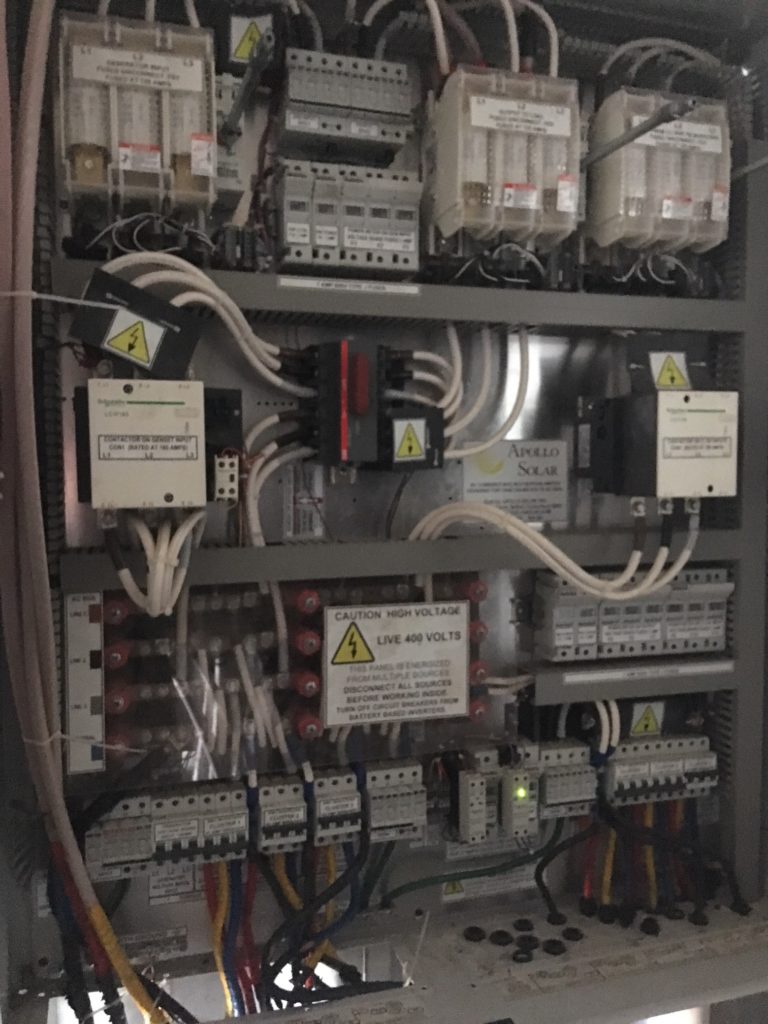

The Utility Grid in South Sudan, as in much of Africa, is 230VAC, 50Hz Single Phase. Supplying a commercial or institutional building would then be done with 400VAC 3-Phase. The stack-ability of the Schneider Electric Conext XW+ inverters, and the diversity of products offered by Schneider Electric make them a popular choice in such a system. Using only products from one manufacturer facilitates communication between the various components of the microgrid system. The Conext Power Distribution Panel (PDP) allows for the stacking of up to 3 XW+ inverters. There are 3 230VAC Single-Phase inverters necessary to provide the 3-Phase power feeding the institution, one for each leg. These are tied together in a PDP, as pictured above. The clusters of battery based inverters in this system, referred to as a Multi-Cluster by Schneider Electric, consist of three inverters per leg of the 3-Phase system, or three PDP’s like the one pictured here. Two such Multi-Clusters are required to provide for the 150kW system installed at the Center. This turns out to be the maximum expansion of the communication system in a Schneider Electric Conext Multi-Cluster System, and the initial cause for STEM Synergy reaching out to Independent Energy Innovations for Expert Renewable Energy System Engineering.

When STEM Synergy’s team in South Sudan installed the system, they were initially confronted with an error code across all of the inverters in one of their Multi-Clusters. In late 2017, an executive with the STEM Synergy contacted an engineer at Independent Energy Innovations to consult on the issues they were facing. We were able to determine that the problem was likely with the master-slave configuration of the inverters in the system. If a master is physically installed as a slave in the system, or is configured improperly in the communications system for its position within the system, the configuration for the entire Multi-Cluster will be thrown off, resulting in the error code reported by the electricians in Juba. Through remote consultation with the electricians at the site, we were able to correct the configuration. In so doing, other issues in the microgrid system were exposed. These issues will be more easily understood after a brief description of the roles of other components and power sources in an AC Coupled microgrid.

In a typical grid tied installation with the CL25E, or any string inverter, the inverter processes the DC power from the array of solar panels into AC power used by the loads and utility grid. As a safety feature, these inverters will shut down if the grid is not detected, so as not to energize lines that the line workers think are dead. An AC signal, at the frequency and voltage of the utility grid is necessary to turn these inverters on. In an AC Coupled system, where grid power is not necessarily present, this signal is provided by the battery based inverters, the XW+ inverters in this system. The grid tie inverters are connected to the AC terminals in the battery based inverters, rather than connected to the electrical distribution panel (the main electrical panel at your house). The battery based inverters can disconnect from the grid, if the utility is down, and power loads from the batteries. In the same manner, the battery based inverters can supply the AC signal necessary for the grid tie inverters to turn on, when there is no utility available, and charge the batteries, and power the loads from the available solar energy. There is also an Automatic Generator Start (AGS) unit attached to the battery based inverters. If the batteries are low, or being drained by the loads, and the solar array has not been producing enough energy, the inverter can turn on a generator, and accept the power from the generator to power loads and charge batteries, as needed. The battery monitors provide the necessary information about the batteries’ state of charge to the XW+ inverters.

This system, then, will ideally produce energy from the solar panels to power the loads and charge the batteries, during the day. Once the Sun goes down, the loads will be powered by the energy stored in the batteries. If the batteries’ state of charge drops below a certain set point, the grid will be connected to power loads and charge the batteries. If the grid is not available, the AGS will turn the generator on to provide the necessary energy. Once the batteries are charged, and/or the solar resource becomes available again, the AGS will stop the generator, and normal operation from the solar array will continue.

In a residential scale AC Coupled system, these connections can all be configured within the battery based inverter, and the PDP. In a commercial scale system, like the one at the center, these connections are all managed through an AC Combiner. The AC Combiner is where the three different energy sources are managed; the grid tie inverters, the battery based inverters, and the grid, or generator if there is no utility. In the AC Combiner, there are Power Meters, to verify which circuits are energized, and the direction of current flow in those circuits. If the current is flowing in the wrong direction, for instance power flowing toward the generator, the Power Meters will open the appropriate Contactors. Before the system could go live, we had to troubleshoot the control circuit between one of the Power Meters and an associated Contactor, remotely. This was an interesting experience, as the System was in South Sudan, and we were working from Arizona, but we were successful in reprogramming the meter, and rebuilding the control circuit. The system went live just days before the Official Opening of the University of Juba STEM Center, which had many highly esteemed South Sudanese in attendance, including Keynote Speaker H.E. James Wani Igga, the Vice President of the Republic of South Sudan. This AC Coupled Multi-Cluster System is the largest Micro-Grid in South Sudan.